Welcome to MC-S – Special Camera Systems! Since 2001, MC-S has been a trusted name in high-speed camera technology, providing innovative imaging solutions that help industries, researchers, and professionals capture motion in extraordinary detail.

As a distributor and integrator of high-speed camera systems, we specialize in delivering precision tools designed to record and analyze fast-moving events. Whether you’re studying intricate mechanical processes, conducting groundbreaking scientific experiments, or creating ultra-slow-motion videos, our advanced cameras deliver the performance and reliability you need.

In addition to high-speed cameras, MC-S offers a range of other specialized products designed to meet diverse imaging and analysis needs:

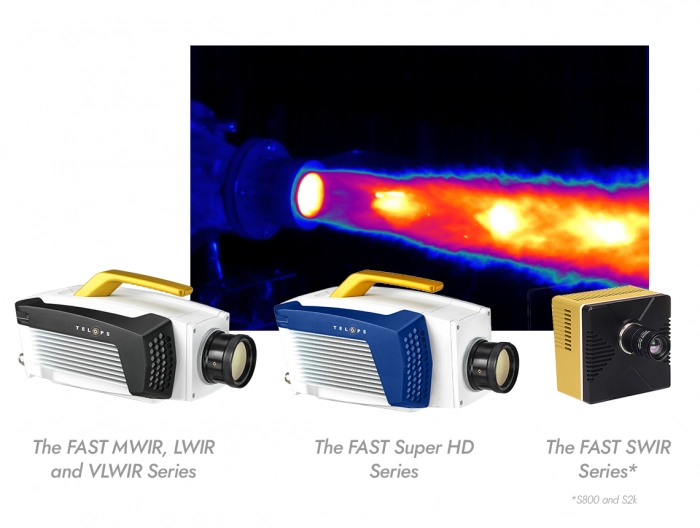

- Thermal Imaging Cameras: Ideal for detecting and analyzing heat patterns in applications like industrial inspections, research, and safety monitoring.

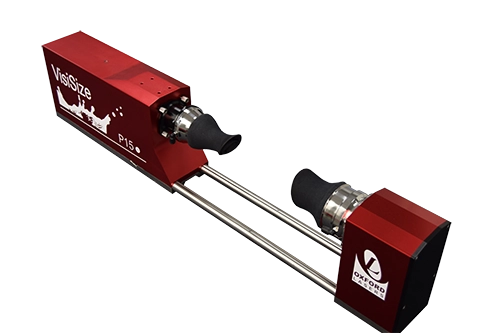

- Hyperspectral Cameras: Cutting-edge imaging technology for capturing and analyzing data across a wide spectrum of wavelengths, ideal for research, agriculture, and material analysis.

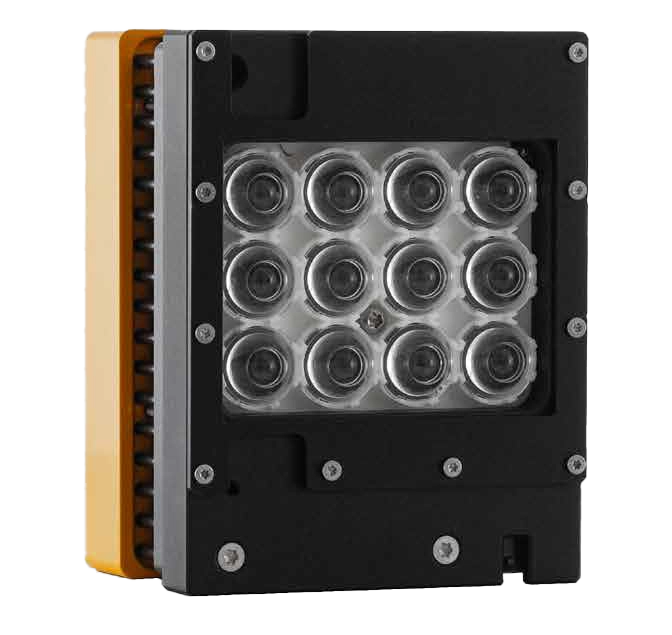

- Laser Illumination: High-intensity, precise lighting systems optimized for high-speed and specialized imaging environments.

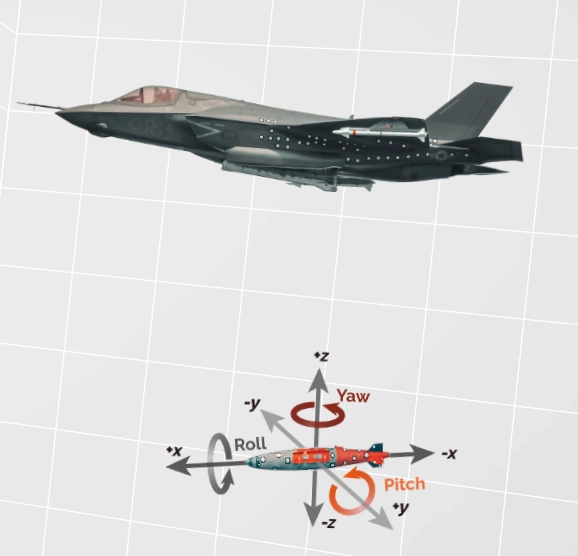

- Motion Analysis Software: Advanced software solutions for detailed analysis of high-speed motion, enabling greater insights into dynamic processes.

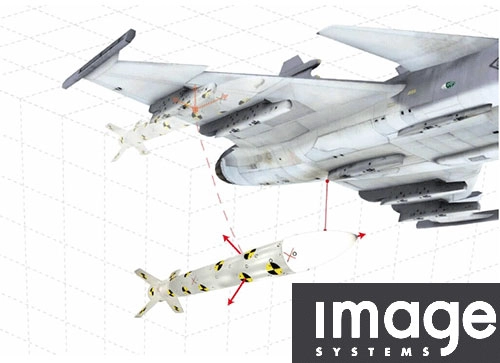

- DIC (Digital Image Correlation) Software: Specialized software for measuring and analyzing deformation, strain, and motion with high accuracy.

- Accessories: A wide range of tools and components to enhance and expand the capabilities of your imaging systems, ensuring they meet the unique demands of your projects.

Why work with MC-S for your imaging needs?

- Proven Expertise: With over 20 years of experience, we understand the unique challenges and requirements of industries like automotive, aerospace, manufacturing, and scientific research.

- Customized Solutions: Every project is different, and we provide tailored systems and products to fit your specific goals and applications.

- Leading Technology: Our portfolio includes state-of-the-art tools and technologies to deliver unparalleled clarity and precision.

- Comprehensive Support: From initial consultation to setup and ongoing assistance, our dedicated team is here to ensure you get the most out of your imaging systems.

High-speed cameras and our range of specialized products are used in a variety of critical applications. These include crash testing for automotive safety, analyzing combustion in engines, studying fluid dynamics, capturing high-speed events in sports, and conducting advanced scientific research. We also collaborate on defense projects such as projectile analysis, projectile tracking, and blast wave research, providing critical insights for safety and innovation. Our solutions support innovations in manufacturing efficiency and product testing, helping industries achieve precision and reliability in their operations.

Find out how our high-speed cameras and other products can make a difference for your work, get in touch with us today!

Welcome to CamMatch!

Unlock the full potential of your next project and find the perfect high speed camera. Simply enter your camera specifications—like resolution, frame rate, and size—into our form below. We’ll analyze your needs and send you a personalized recommendation that best fits your project’s requirements.